16 FUTURISTIC BUILDING MATERIALS

Future

buildings could be made of artificial human bone, hemp, bacterial by-products or

concrete that absorbs greenhouse gas emissions and lasts thousands of years.

Innovations in building materials have led to synthetic creations that are

stronger, lighter and more sustainable than those we already use, potentially

leading to architecture unlike anything we’ve ever seen before.

1. Animal

Blood Bricks

Abundant

and yet almost always wasted, animal blood is an unlikely - and grisly -

possible base material for building bricks. Architectural graduate Jack Munro

sterilized the blood, added sand and baked them together to yield a strong,

traditional-looking brick that’s also waterproof.

2.

Translucent Concrete

Litracon is a combination of optical

fibres and fine concrete, produced as prefabricated building blocks for a

translucent glass-like look with surprising strength. It’s hand-made, so each

block has its own individual pattern of light.

3.

Bacteria Building Blocks

Will

bacteria build the walls of our

houses in the

future? Scientists have directed the creation of bio-plastics, cellulose and

other materials by feeding certain materials to specific varieties of bacteria.

The resulting metabolic process produces solid, surprisingly durable by-products

that could be used for all kinds of processes. Bacteria might even create bricks

that could be used for building on

Mars.

4.

Concrete That Lasts 16,000 Years

Not only

would the new concrete being developed at

MIT drastically

reduce the carbon emissions currently associated with the manufacturing of this

material, it would also result in an astonishing reduction in the amount needed

in the first place. That’s because it’s strong enough to last for an incredible

16,000 years. This concrete will not only be stronger, but also lighter and

thinner, so large-scale, lightweight structures require far less

material.

5.

Hempcrete: Hemp Biocomposite

A new

bio-composite, thermal wall material made of

hemp, lime and

water is not only eco-friendly but actually carbon-negative thanks to the amount

of CO2 stored during the process of growing and harvesting hemp. It’s 100%

recyclable, waterproof and fireproof and could be used for everything from walls

and insulation to flooring. Once demolished, the material can be used as

fertilizer.

6.

SensiTile

Sensitiles are made up of a

light-conducting matrix embedded in a substrate, so that they redirect and

scatter incoming light in a similar way as fibre optics. Shadow-producing

movements around these tiles produce an interesting rippling effect, and the

tiles absorb and ‘bleed’ colours.

7.

Bendable Concrete

A

new type of concrete

can not only

bend under 5% tensile strain, it does so by self-healing. The material forms

micro-cracks when bent, which then seal themselves after being exposed to water

and carbon dioxide.

8.

Water-Saving Bricks

What

looks like an ordinary red brick on one side contains a waterway that can route

water down the side of a building and into a basin for bathrooms, fountains,

cleaning, fire fighting or irrigation. The ‘Save Water’

brick is made of

pulverized fallen leaves and reclaimed plastic.

9.

Aerogel

So light

you can’t even feel it in your hand, aerogel has the lowest bulk density of

any known porous solid, and it’s a powerful insulating material. Made up of a

gel that has had its liquid component replaced by air, it’s thin, breathable,

fireproof, strong and won’t absorb water. Manufacturers are now producing it in

sheets as insulation, but it’s still pretty expensive.

10.

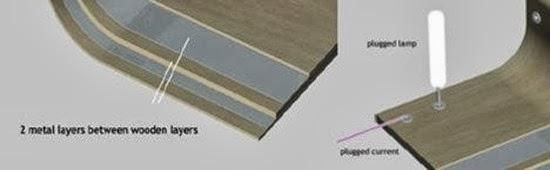

Electrified Wood

A

composite material made of pre-formed wooden elements and metal layers actually

enables lamps and other electronics to be plugged directly into the wood without

any cables. Developed by trans|alpin, the electrified wood

material could

revolutionize furniture.

11.

Liquid Granite

Safer at

high temperatures than concrete, but just as versatile, ‘liquid granite’ is made of 30-70% recycled

material and uses less than a third of the cement used in precast concrete. It

could be used in building projects that require the top level of protection

against fire.

12.

Novacem Carbon-Eating Cement

2.9

billion tons of cement is produced every year, and it’s responsible for up to 5%

of the world’s annual production of CO2. Novacem, a cement substitute made of

magnesium silicate, actually absorbs CO2 from the atmosphere. It could

potentially achieve one of the single largest reductions in CO2 emissions in

construction, cutting out 800kg of carbon emissions per ton of poured concrete

and absorbing another 50kg.

13.

Flexicomb

Made

from drinking straws, a disposable product, ‘flexicomb‘ is a flexible material that

form a translucent honeycomb matrix that could potentially be used to make

lighting fixtures and other items.

14.

Kinetic Glass

A new

material called ‘living glass’ could monitor CO2 levels in the

air, automatically opening and closing its ‘gills’ in response to the breathing

of humans in the room. It’s made of silicone embedded with wires that contract

due to electrical stimulus, allowing the gills to regulate air quality when

carbon dioxide levels are high.

15.

Zeoform: Recyclable, Low-Carbon

Using

nothing more than cellulose and water, this hardwood-like material is an

eco-friendly alternative to plastics and resins. Zeoform is made using a natural

glue-free process whereby cellulose fibres stick

together in water, and can be sprayed, moulded or shaped into a wide range of

objects.

16.

Artificial Bone

Human

bone is the inspiration behind a new high-tech

composite that

can be made in just a few hours using a 3D printer. Just as collagen and

hydroxyapatite help a natural bone withstand fracturing by dissipating energy

and distributing damage over a larger area, so do a soft black polymer and a

stiff blue polymer acting like a brick-and-mortar wall. The 3D printed bone

material is 22 times more fracture-resistant than any of its parts, and one day,

it could be used as the basis of entire buildings.

No comments:

Post a Comment