Must have for Christmas!

PicoBrew Zymatic aims at almost completely automatic beer brewing

PicoBrew aims to automate home beer brewing, with the Zygomatic

What does making bread and brewing espresso have in common? Not long ago, both were involved, messy jobs best left to the experts that can now be done at home by anyone who can pour ingredients and press a button. PicoBrew LLC of Seattle wants to do the same with beer, with the PicoBrew Zymatic – a countertop brewery that is claimed by the developers to be as automatic as a breadmaker.

The focus of a Kickstarter campaign that runs through October 30, the Zymatic is billed as a way of making home brewing completely automatic. Currently, making your own beer at home is a very involved, imprecise process where the results can be as reliable as a crapshoot and clean-up is a long, tedious process. PicoBrew’s goal is to reduce brewing to a series of precisely controlled, computer-monitored steps where the user’s role is no harder than selecting recipes and adding ingredients.

It’s the brainchild of Bill and Jim Mitchell, the former a one-time Microsoft developer and the latter a builder of food processing machines, who decided in 2010 to build a compact, easy-to-clean automatic brewing machine. Later joined by electrical and mechanical engineer Avi Geiger, they went through a series of prototypes. These started with an off-the-shelf Arduino-based controller, standard pumps, relays, valves and a custom heating loop before progressing to bespoke electronics and mechanics, as they refined the device’s ability to control aspects of the brewing process (such as mash efficiency and hops utilization) and improved its reliability. Along the way they conducted testing and tasting with local amateur and professional brewers.

Some examples of PicoBrewed beer

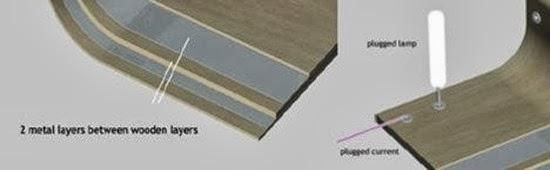

In its current configuration, the Zymatic is a steel box about the size of a camping oven with a simple pull-out plastic drawer in front that holds the ingredients and can be cleaned in a dishwasher. The main compartment of the drawer holds the grain and a smaller compartment called the step filter holds smaller ingredient containers called “cages” for hops and the like. Hoses coming from the side of the Zymatic connect it to a 5-gallon (19-liter) cornelius keg.

To use the Zymatic, you select a recipe from the rotary encoder on the front of the machine, load one using the web-based PicoBrew Recipe Crafter, or select from online recipes. The machine maintains a tight control of temperature and other variables and provides a readout of results.

With the recipe loaded, you then attach the cornelius keg filled with water using the hoses, add the hops and other ingredients according to the recipe into the step filters, close the drawer, and start the machine. According to PicoBrew, in about 3.5 hours the Zymatic will pump the resulting unfermented beer wort back into the keg. Then it's a matter of plunging the keg into a bucket of ice water to cool it, adding yeast, and then either transferring the beer to a clean keg to ferment, put it directly in a kegerator and adding carbonation, or bottling it as preferred.

According to PicoBrew, the Zymatic is still in the final stages of development. A pledge of US$1,299 will get you one, when and if they reach commercial production. By contrast, the already-available WilliamsWarn brewing machine sells for approximately $5,000.

PicoBrew says that if it keeps to schedule, the

first units should ship in January.

The video below introduces the Zymatic.

Sources:

PicoBrew,

Kickstarter via

Seattle Times

The results showed that the song Weightless was 11 per cent more relaxing than any other song and even caused drowsiness among women in the lab.

The results showed that the song Weightless was 11 per cent more relaxing than any other song and even caused drowsiness among women in the lab.